Multi-Axis machining represents a cutting-edge advancement in the field of computer numerical control (CNC) machining, transforming the way manufacturers create intricate and complex components. This multidirectional movement capability enables the production of highly intricate parts with unprecedented precision and efficiency.

Multi-Axis machining finds applications in diverse industries, including aerospace, automotive, medical, and electronics, where complex geometries and high-quality finishes are paramount. By enhancing flexibility, reducing setup times, and minimizing material wastage. Benefits Multi-axis Machining are discussed here as this machine has become instrumental in the production of critical components, driving innovation and setting new standards for precision engineering.

Its ability to tackle intricate designs and deliver superior surface finishes positions it as a cornerstone technology in modern manufacturing, enabling businesses to meet the demands of increasingly complex and sophisticated engineering challenges.

Benefits of Multiaxis Machining

The X, Y, and Z axes are the three directions in which standard CNC machining methods, like 3-axis CNC machining, can move. It is furthered by adding one or more axes to the cutting tool movement through multi-axis machining. Moreover, it is typical to divide the additional axes of movement between the workpiece and the cutting tool.

Complex Geometries

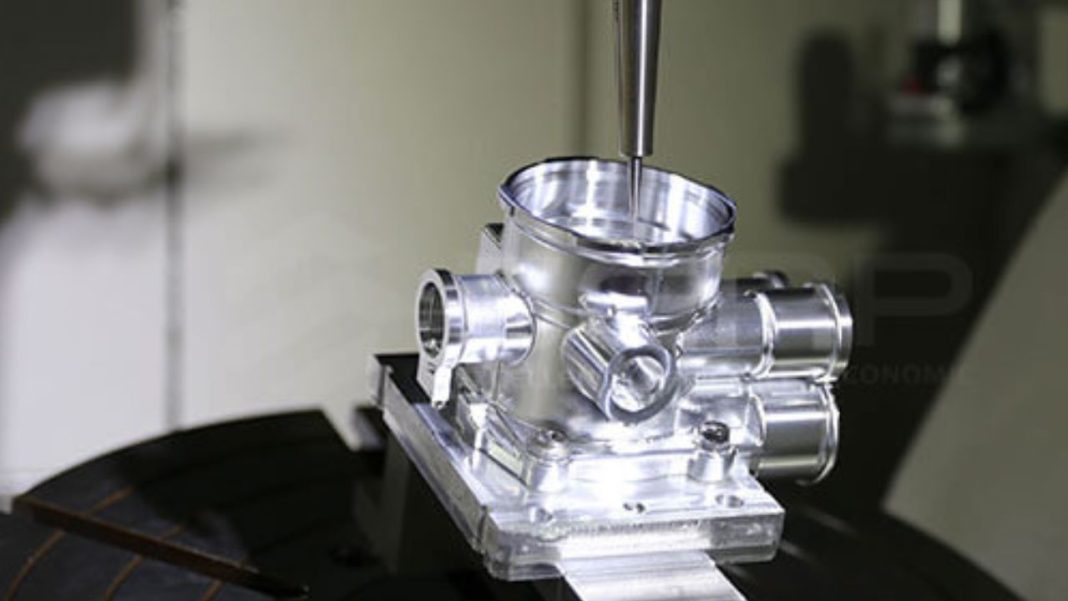

Multi-axis machining can create complex geometries and features that would be challenging or impossible to achieve with traditional machining methods. This capability is invaluable for producing prototypes, custom components, and intricate molds.

Shorter Production Time

By enabling simultaneous machining from multiple angles, multi-axis CNC machines can significantly reduce production time. They can handle complex cuts in a single pass, streamlining the manufacturing process and accelerating time-to-market for products.

Enhanced Accuracy

Because multi-axis CNC machines enable the cutting tool to follow complex toolpaths with no operator intervention, they provide higher precision. Manufacturing high-tolerance components for the aerospace, automotive, and medical device industries requires this level of precision.

Improved Surface Finish

Multi-axis CNC machines excel in providing superior surface finishes on machined components. The simultaneous movement along multiple axes allows the cutting tool to follow intricate toolpaths, resulting in smooth and polished surfaces. This high-quality surface finish is particularly important in applications where aesthetics and functionality are paramount, such as consumer electronics and high-end automotive components.

Enhanced Tool Life

Multi-axis CNC machining optimizes tool engagement with the workpiece. By approaching the material from various angles, the cutting forces are distributed more evenly across the tool, reducing wear and extending tool life. This results in fewer tool changes, minimizing downtime, and reducing tooling costs for manufacturers. Enhanced tool life also contributes to cost-effectiveness and improved overall efficiency in the production process.

Versatility and Adaptability

Multi-axis CNC machines are incredibly versatile and adaptable to a wide range of materials and applications. Whether machining metals, plastics, composites, or exotic alloys, these machines can handle diverse materials with varying hardness levels. Additionally, they can accommodate different sizes and types of workpieces, making them suitable for both small-scale precision machining and large-scale production runs. This adaptability ensures that manufacturers can meet the demands of diverse industries and applications.

Innovation and Design Freedom

The flexibility offered by multi-axis CNC machining encourages innovation and design freedom. Engineers and designers can explore creative and intricate designs without being limited by manufacturing constraints. This freedom to innovate leads to the development of groundbreaking products and components that push the boundaries of technology and design. Whether in the aerospace industry, where lightweight and aerodynamic components are essential or in the art and sculpture industry, where intricate designs come to life, multi-axis CNC machining empowers creative expression and innovation.

Final Wording

Multi-axis CNC machining stands at the forefront of advanced manufacturing technologies, offering unparalleled precision, efficiency, and versatility. Its ability to create complex geometries, enhance surface finishes, and optimize tool life makes it indispensable in various industries. As technology continues to evolve, multi-axis CNC machining is expected to further revolutionize the manufacturing landscape, driving innovation, improving product quality, and enabling the production of highly sophisticated components that shape the future of numerous industries.